Qingdao Haorui Steel Products Co., Ltd.

Mob: 15966945003

Contact: Yanan Wang

Tel: 0532-87881070

Fax: 0532-87980111

Email: wang@qdhaorui.com

Add: No. 375, Zhengyang East Road, Xifu Town, Chengyang District, Qingdao

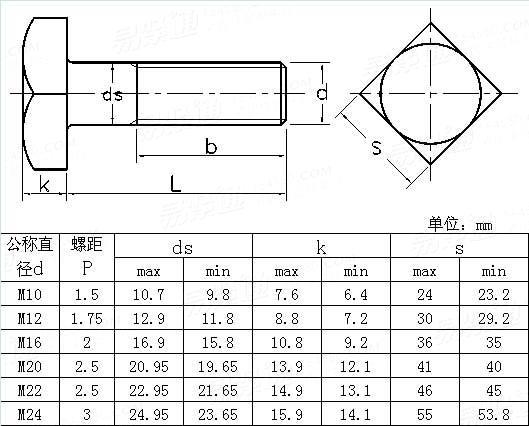

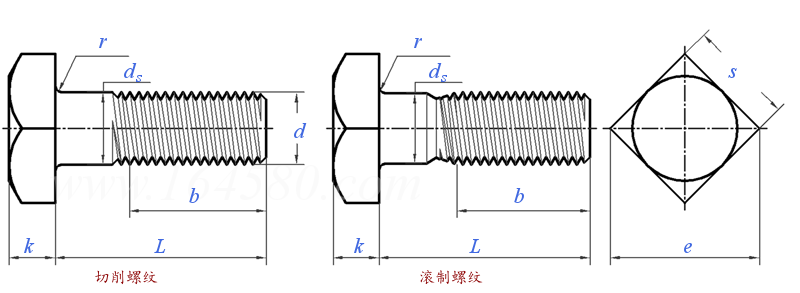

Square head bolts refer to bolts with a square head. This type of bolt is composed of a square bolt head and a screw (cylinder with external threads). According to the shape of the head, it is divided into large square head bolts and small square heads. Bolts, square oblique head bolts, square countersunk head bolts, square head thick rod bolts, etc. Qingdao Haorui Steel Products Co., Ltd. produces all kinds of inch bolts, metric bolts, and American bolts, professionally supplies hardware, and processes custom-made bolts, rivets, and special-shaped fasteners.

Explanation of some terms related to square head bolts---hardness:

Hardness indicates the ability of a material to resist hard objects pressed into its surface. Generally, the higher the hardness, the better the wear resistance. Commonly used hardness indicators are Brinell hardness, Rockwell hardness and Vickers hardness.

1. Brinell hardness (HB) Press a hardened steel ball of a certain size (usually 10mm in diameter) into the surface of the material with a certain load (usually 3000kg), keep it for a period of time, after removing the load, the ratio of the load to the indentation area , Is the Brinell hardness value (HB), the unit is kilogram force/mm2 (N/mm2).

2. Rockwell hardness (HR) When HB>450 or the sample is too small, the Brinell hardness test cannot be used and the Rockwell hardness measurement can be used instead. It uses a diamond cone with an apex angle of 120° or a steel ball with a diameter of 1.59 and 3.18mm, which is pressed into the surface of the material to be tested under a certain load, and the hardness of the material is obtained from the depth of the indentation. According to the hardness of the test material, it is expressed in three different scales: HRA: It is the hardness obtained with a 60kg load and a diamond cone indenter, and is used for materials with extremely high hardness (such as cemented carbide, etc.). HRB: It is the hardness obtained by using a 100kg load and a hardened steel ball with a diameter of 1.58mm, which is used for materials with lower hardness (such as annealed steel, cast iron, etc.). HRC: It is the hardness obtained with a load of 150kg and a diamond cone indenter. It is used for materials with high hardness (such as hardened steel, etc.).

3. The Vickers hardness (HV) is pressed into the surface of the material with a load within 120kg and a diamond square cone indenter with an apex angle of 136°. The surface area of the material indentation pit is divided by the load value to obtain the Vickers hardness value. (HV). From the above introduction, Vickers hardness is one of the surface hardness. There is a conversion relationship between it and other hardness units.

Previous: Square head bolt

下一条: Square head bolt